When dealing with settling or sunken concrete surfaces, homeowners and businesses alike seek reliable solutions to restore the integrity of their structures. In Atlanta, two common methods for lifting and leveling concrete are compaction grouting and mudjacking. While both processes serve the same purpose, compaction grouting offers several distinct advantages that make it the superior choice for concrete lifting projects in the area. This article will explore grout chemistry, void fill process, and curing times, showing why compaction grouting stands out as the more efficient and effective solution for concrete lifting in Atlanta.

Introduction To Concrete Settlement

Concrete settlement can be caused by various factors, including soil erosion, water infiltration, or the natural settling of the earth beneath a concrete slab. Over time, these shifts create voids beneath the concrete, causing it to sink or crack. To address this issue, a lifting technique is needed to fill the voids and restore the concrete to its original position. Traditional methods like mudjacking have been used for decades, but the advanced concrete lifting and compaction grouting in Atlanta has proven to be a better choice for long-term stability.

The Grout Chemistry: Compaction Grouting Vs. Mudjacking

At the core of both mudjacking and compaction grouting is the use of a grout material to fill voids beneath the concrete. However, the materials and their respective chemical compositions differ significantly, leading to distinct outcomes.

Mudjacking utilizes a mixture of sand, cement, and water, often referred to as a “mud slurry.” This slurry is injected into the voids under pressure, where it flows beneath the slab to lift it back into position. While effective, mudjacking’s grout mixture can be prone to erosion over time, particularly if the water content is too high. This can lead to the reappearance of settled concrete, requiring further treatment.

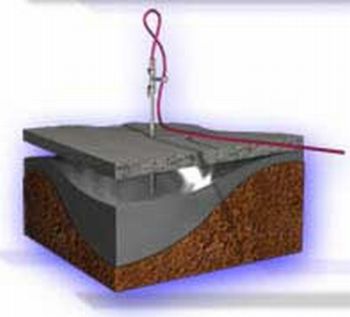

Compaction Grouting, on the other hand, employs a much denser grout mixture. It typically consists of a combination of cement, water, and fine aggregates. The grout is designed to be thicker and more durable than the slurry used in mudjacking. When injected into the void, the grout compacts the surrounding soil while simultaneously filling the voids, ensuring a more stable and lasting solution. The process also helps to densify the soil beneath the concrete, reducing future settlement risks.

The more robust nature of the compaction grout ensures that it does not erode as easily as mudjacking material. Moreover, the compaction grouting process provides a stronger bond between the grout and the surrounding soil, making it far less likely to suffer from future voids or further sinking.

Voids And How They Are Filled

The effectiveness of a concrete lifting method largely depends on how well the voids beneath the slab are filled. In both methods, grout is injected through small holes drilled into the concrete, but the way each technique fills the void is different.

Mudjacking works by filling the voids with a slurry that expands under pressure. This expansion helps lift the concrete slab, but it does not necessarily address the cause of the settlement. Since the slurry is fluid, it tends to flow and fill the spaces where pressure is highest, which may lead to uneven lifting or incomplete filling of all the voids. Over time, the slurry may also wash away or lose its ability to support the weight of the concrete, leading to the need for repeated treatments.

Compaction Grouting, however, is a more controlled process. The grout mixture used in compaction grouting is designed to be thicker and more viscous, allowing it to fill the voids more effectively. The grout is injected under high pressure, which forces it to fill the voids completely while compacting the surrounding soil. This method provides a more uniform lifting of the concrete and creates a stable base for the slab, minimizing the likelihood of future settlement.

By filling the voids and compacting the surrounding soil, compaction grouting offers a more permanent solution to concrete sinking. Unlike mudjacking, which may need to be repeated in the future, compaction grouting often eliminates the problem for good, making it a better investment for homeowners and businesses in Atlanta.

Curing Times And Effectiveness

Another key advantage of compaction grouting over mudjacking is the curing time. Mudjacking requires the grout to cure slowly over several days. The high water content of the mixture can cause it to take longer to solidify, which may lead to delays in using the concrete surface. During this curing period, the lifted concrete is vulnerable to shifts and movement, and there is a risk that the slurry will not properly bond with the surrounding soil, leading to instability.

Compaction Grouting, however, provides a much quicker curing time. The thicker consistency of the grout used in this method allows it to set faster, often within a few hours, depending on the specific mixture. As the grout sets, it solidifies quickly, locking the concrete into place with minimal risk of future shifting or settlement. This faster curing time allows homeowners and businesses in Atlanta to resume their activities much sooner without worrying about potential delays or complications in the process.

Advanced Concrete Lifting And Compaction Grouting In Atlanta

In Atlanta, compaction grouting has become the preferred method for concrete lifting, particularly for larger commercial projects or areas with significant soil instability. It offers a higher level of precision, a more durable outcome, and a quicker turnaround time compared to mudjacking. Whether you’re dealing with settling sidewalks, driveways, or foundation slabs, compaction grouting provides a superior solution that minimizes the risk of future issues.

Choosing the right method for concrete lifting in Atlanta comes down to the long-term effectiveness and reliability of the solution. With compaction grouting, homeowners and businesses are making a wise investment in the future stability of their structures, ensuring that their concrete surfaces remain level, safe, and functional for years to come.