In the fast-evolving world of modern production, automated visual inspection in manufacturing has become one of the most powerful enablers of efficiency, accuracy, and consistent quality. From automotive components and semiconductor chips to consumer electronics and pharmaceuticals, industries are now turning to advanced imaging systems powered by artificial intelligence (AI) and machine learning (ML) to redefine how they detect defects, maintain quality, and streamline the entire production cycle.

Understanding Automated Visual Inspection

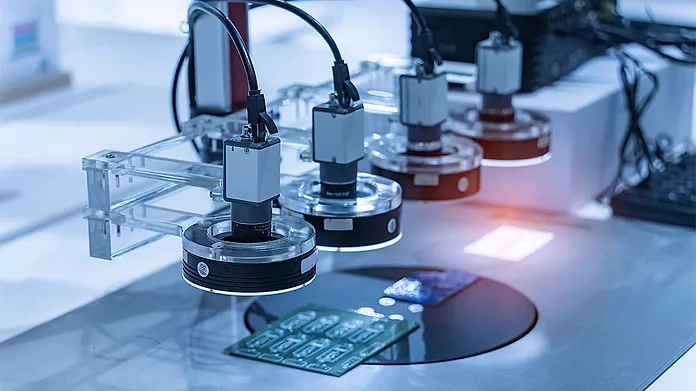

At its core, automated visual inspection (AVI) refers to the use of advanced cameras, lighting systems, and intelligent algorithms to visually inspect products and components during manufacturing. Unlike traditional manual inspection—where human workers rely on sight and experience—AVI systems employ high-resolution imaging and AI models to instantly detect imperfections such as scratches, dents, misalignments, and color inconsistencies.

These systems are capable of operating at high speeds, often integrated directly into production lines, where they provide real-time feedback to control systems. The result is a more reliable, faster, and objective quality assessment process that minimizes human error and production downtime.

Why Manufacturers Are Embracing AVI

Manufacturers across industries are adopting automated visual inspection in manufacturing for several critical reasons:

- Consistency and Accuracy – Human inspection is inherently subjective. AVI systems deliver uniform accuracy 24/7, detecting even microscopic defects invisible to the naked eye.

- Speed and Efficiency – With high-speed cameras and image processors, AVI systems can inspect thousands of parts per minute—an impossible feat for manual methods.

- Cost Reduction – Early detection of defects prevents waste, rework, and returns, leading to significant cost savings over time.

- Traceability and Data Insights – Advanced systems collect inspection data, allowing manufacturers to trace defects back to their sources and identify recurring issues in real time.

- Regulatory Compliance – For industries like pharmaceuticals, aerospace, and automotive, AVI ensures that every product meets stringent compliance standards.

The Technology Behind Automated Visual Inspection

Automated visual inspection systems are built on several key technological pillars:

- High-Resolution Cameras and Sensors: Capture ultra-detailed images of each product from multiple angles.

- Lighting Control Systems: Proper illumination is crucial to detect subtle variations or surface defects.

- Machine Vision Software: AI-powered algorithms process images and identify anomalies.

- Deep Learning Models: Trained on thousands of images, these models improve over time, recognizing even new defect types.

- Integration with IoT and Cloud Platforms: Enables real-time data sharing, predictive maintenance, and centralized quality control across multiple production facilities.

Together, these technologies make AVI systems adaptable and scalable—suitable for both small-scale assembly lines and global industrial operations.

Applications Across Industries

The reach of automated visual inspection in manufacturing extends far beyond one sector. Here’s how different industries are leveraging it:

- Automotive: Ensures precision in assembly, paint finish, and component alignment, reducing recall risks.

- Electronics: Detects soldering issues, missing components, and micro-defects on PCBs with near-perfect accuracy.

- Pharmaceuticals: Verifies packaging integrity, label accuracy, and contamination in sterile environments.

- Food & Beverage: Inspects packaging seals, fill levels, and labeling to maintain hygiene and brand standards.

- Metal & Plastics: Monitors surface finishing, dimensions, and uniformity in materials used for production.

Each application underscores AVI’s versatility in driving higher yield rates, faster throughput, and unwavering product quality.

Benefits That Redefine Manufacturing Operations

Implementing AVI doesn’t just improve inspection—it transforms the entire manufacturing ecosystem.

- Predictive Quality Control: By analyzing inspection data trends, AI models can predict future defects, allowing teams to take preventive action.

- Reduced Downtime: Early anomaly detection helps prevent breakdowns or equipment malfunctions.

- Enhanced Production Flexibility: AVI systems can be reprogrammed for new product designs or inspection parameters, supporting agile manufacturing.

- Improved ROI: Although initial investment costs can be high, long-term benefits like reduced waste and labor costs yield substantial returns.

In short, the adoption of automated inspection systems creates a smarter, faster, and more data-driven factory floor.

Challenges and Considerations

While the benefits are undeniable, adopting automated visual inspection in manufacturing comes with challenges that companies must address carefully:

- Implementation Costs: High-end imaging systems and AI software require upfront investment.

- Complex Integration: Aligning AVI with existing ERP or MES systems can demand technical expertise.

- Data Management: Handling massive image datasets and ensuring cybersecurity can be complex.

- Continuous Model Training: AI models require constant updates with new defect images to maintain accuracy.

However, as technology advances and costs continue to fall, these challenges are gradually becoming easier to overcome. Many manufacturers now rely on cloud-based AVI systems that simplify deployment and scale with production growth.

Steps to Successfully Implement AVI Systems

- Define Inspection Goals: Identify key checkpoints in your production where inspection can add maximum value.

- Select Suitable Hardware: Choose the right combination of cameras, sensors, and lighting for your specific product type.

- Integrate with Existing Systems: Ensure seamless connectivity between AVI, MES, and production analytics tools.

- Train AI Models Effectively: Feed diverse and well-labeled image datasets for accurate model training.

- Monitor and Optimize: Use feedback loops to continuously refine detection algorithms and eliminate false positives.

A thoughtful approach ensures the system not only detects defects but also contributes to broader operational excellence.

The Future of Automated Visual Inspection

The next decade will see automated visual inspection in manufacturing evolve from a quality control tool into a fully autonomous decision-making system. AI models will not only detect but also correct anomalies in real time, aided by robotics and edge computing. With 3D imaging, hyperspectral cameras, and AI-powered analytics, inspection systems will soon operate at the intersection of precision and intelligence—making factories truly self-optimizing environments.

Sustainability will also become a driving force. AVI systems can help reduce waste, energy use, and rework, aligning manufacturing with global green initiatives.

Final Thoughts

In today’s competitive industrial landscape, maintaining quality is no longer enough—it’s about achieving perfection at scale. Automated visual inspection in manufacturing empowers businesses to combine accuracy, agility, and intelligence in one integrated process. Whether you’re a small-scale producer or a global manufacturer, adopting AVI technology represents not just an upgrade in inspection—but a strategic leap toward the future of smart manufacturing.

By leveraging AI-driven precision, real-time analytics, and continuous improvement, automated visual inspection is transforming how products are made, verified, and delivered to the world—one flawless detail at a time.